White cardboard stiffness directly influences its printing performance. It affects sheet feeding, ink adhesion, and overall print quality. This analysis explores how varying GSM impacts these critical aspects for materials like FBB Paper Board and One Side Ivory Board, including products such as ningbo fold board from APP.

Key Takeaways

- Cardboard’s GSM shows its weight and thickness. Higher GSM means heavier, thicker cardboard.

- Stiffer cardboard helps printing. It feeds smoothly, holds ink well, and keeps images aligned.

- Choose cardboard based on its use. Match its GSM and stiffness to your printer and final product needs.

Understanding GSM in White Cardboard Properties

Defining GSM for White Cardboard

GSM, or Grams per Square Meter, is a standard measure for paper weight. It indicates the amount of grams one square meter of paper weighs. This metric is the global standard for expressing paper weight. It represents the weight in grams of a single sheet of paper measuring one meter by one meter. A lower GSM means lighter, thinner paper, while a higher GSM signifies heavier, thicker cardstock. GSM measures weight, but heavier papers are generally thicker.

Common GSM Ranges and Applications of White Cardboard

White cardboard offers a wide GSM range, typically from 190 GSM to 400 GSM or higher. This flexibility allows businesses to choose the right thickness for their needs. Lighter GSM boards are easy to handle and cost-efficient for high-volume printing. Heavier boards provide superior structure for boxes and covers. These heavier boards require enhanced protection and offer a premium feel. White cardboard is ideal for cosmetic boxes, business cards, and pastry boxes.

Fiber Density and Thickness Contributions to White Cardboard GSM

Fiber density and thickness directly contribute to a white cardboard’s GSM. A higher density of fibers within the paper structure increases its weight per square meter. Similarly, greater thickness also leads to a higher GSM. For example, a 210 GSM board typically has a thickness of 0.27 mm, while a 400 GSM board can reach 0.55 mm in thickness. This relationship shows that as GSM increases, the board generally becomes thicker and more robust.

The Direct Relationship Between GSM and White Cardboard Stiffness

Defining Stiffness and Measurement Methods

Stiffness describes a material’s resistance to bending or deformation under an applied force. It is a critical mechanical property for paperboard materials. Industry standards provide clear methods for measuring this characteristic. For instance, ISO 5628 specifies three primary test methods for determining stiffness under flexure: the 2-point, 3-point, and 4-point flexure tests. The 2-point and 3-point methods are suitable for thinner paper and cardboard. The 4-point flexure method is recommended for thicker corrugated board and cardboard. Additionally, DIN 53121 describes the width-related determination of flexural strength using the beam method. ISO 2493-1 also specifies methods for determining the flexural strength of paper and cardboard based on two-point loading.

Specialized equipment helps assess stiffness accurately. Common methods include the bending test (BNT) and the four-point bending test. Non-contact measurement methods, such as video extensometry and digital image correlation (DIC), measure displacement and strain. These methods help determine key mechanical parameters like bending stiffness (BS). Instruments like the Texture Analyser range and the Three Point Bend Rig perform flexural stiffness tests. These tests indicate a material’s resistance to deformation when bent.

GSM and Stiffness Correlation in White Cardboard

A direct relationship exists between a white cardboard‘s GSM and its stiffness. Generally, as the GSM increases, the stiffness of the cardboard also increases. A higher GSM indicates more material per square meter. This means the board contains more fibers and possesses greater thickness. More material provides increased resistance to bending forces. Therefore, a 300 GSM board will typically be much stiffer than a 200 GSM board of the same type. This enhanced stiffness contributes significantly to the material’s structural integrity. It also improves its handling properties during various processes.

Factors Influencing White Cardboard Stiffness Beyond GSM

While GSM is a primary indicator of stiffness, other factors also play a significant role. Environmental conditions, for example, heavily influence the mechanical behavior of paperboard. Changes in temperature and relative humidity can complicate the assurance of product-packaging integrity. The moisture content of white cardboard is a crucial factor. It significantly impacts the material’s quality and performance, including its strength and durability.

Changes in relative humidity (RH) have significant adverse effects on the mechanical properties and fiber network strength of paperboard. Increased moisture content due to RH changes can lead to higher rates of compressive creep. This is particularly relevant for stacked packages during long-term transportation and storage. Therefore, maintaining stable environmental conditions is essential for consistent stiffness performance. Other factors like fiber type, fiber orientation, and the manufacturing process (e.g., calendering) also contribute to the final stiffness characteristics.

Impact of White Cardboard Stiffness on Printing Performance

The stiffness of white cardboard significantly influences its performance throughout the entire printing process. This critical property affects everything from how sheets move through the press to the final appearance and durability of the printed product. Printers must understand these impacts to achieve optimal results.

Sheet Feeding and Handling with Varying Stiffness

The stiffness of white cardboard directly affects how printing presses feed and handle individual sheets. Stiffer boards generally feed more smoothly and consistently through high-speed printing equipment. They resist buckling and creasing as they travel along conveyor belts and rollers. Boards that lack sufficient stiffness can cause frequent jams, misfeeds, and production delays. This leads to increased waste and reduced efficiency. Printers often adjust machine settings, such as air pressure and gripper tension, to accommodate different stiffness levels. However, excessively flexible boards remain challenging to manage, regardless of adjustments.

Ink Adhesion and Absorption on Stiff White Cardboard

Stiffness also plays a crucial role in how ink adheres to and absorbs into the white cardboard surface. Stiffer boards often possess a more uniform and stable surface. This allows for better ink transfer and more consistent ink film thickness. A stable surface minimizes uneven ink absorption, which can lead to blotchy or faded print areas. When the board is too flexible, it can deform slightly during ink application. This causes inconsistent pressure from the printing plate or blanket. This inconsistency can result in poor ink adhesion, smudging, or a lack of sharpness in the printed image. The structural integrity of a stiffer board helps maintain optimal contact between the printing surface and the ink.

Print Registration and Dimensional Stability of White Cardboard

Maintaining precise print registration is essential for high-quality multi-color printing. The stiffness of white cardboard directly contributes to its dimensional stability. This stability ensures that the sheet retains its shape and size throughout multiple passes through the press. A dimensionally stable board prevents shifts that could misalign colors or images.

Paper that is too soft may compress unevenly, causing registration errors, ink smearing, or color variation.

Stiffer boards resist stretching or shrinking due to changes in temperature, humidity, or mechanical stress during printing. This resistance is vital for achieving sharp, perfectly aligned graphics and text. Poor dimensional stability, often linked to insufficient stiffness, leads to blurry images and unacceptable print quality.

Post-Printing Processes and White Cardboard Stiffness

The stiffness of white cardboard extends its influence beyond the printing stage into various post-printing processes. These processes include cutting, creasing, folding, embossing, and die-cutting. Stiffer boards provide cleaner, more precise cuts and creases. This is because they resist tearing or fraying at the edges. When folding, a stiff board creates sharp, defined folds without cracking the surface. This is particularly important for packaging and promotional materials. For embossing and debossing, a firm substrate allows for deeper, more detailed impressions. Boards with inadequate stiffness can lead to imprecise cuts, ragged folds, and shallow, poorly defined embossed features. This compromises the final product’s aesthetic appeal and structural integrity.

Analyzing Multi-GSM White Cardboard Scenarios

Low GSM White Cardboard: Challenges and Advantages

Low GSM white cardboard offers cost efficiency and easy handling for high-volume printing. However, it presents specific challenges. This material is susceptible to curling and buckling. Environmental factors like humidity fluctuations cause the paper to stretch or shrink. This leads to waviness or cockling before printing. If paper fibers shift during manufacturing, increased humidity creates diagonal tensions. These tensions result in curling paper edges. Printers can counteract curling. They apply a thin layer of water-based varathane to the material’s bottom side. This balances tension and prevents curling when cutting or applying ink.

Medium GSM White Cardboard: Optimal Balance for Printing

Medium GSM white cardboard often provides an optimal balance for many printing applications. It offers sufficient stiffness for reliable sheet feeding and handling. This GSM range also supports good ink adhesion and print registration. It avoids the extreme flexibility of lower GSM options. It also avoids the cost implications of very high GSM boards. Printers find this range versatile for brochures, flyers, and standard packaging. It delivers quality results without excessive material costs or specialized equipment needs.

High GSM White Cardboard: Benefits and Considerations

High GSM white cardboard offers significant benefits for demanding printing applications. It is thicker and more durable. This enhanced durability helps the paper resist bending and tearing. Dense papers with higher GSM last longer. They also provide a premium feel. These characteristics make it ideal for luxury packaging or special invitations. However, high GSM paper typically costs more. This is due to increased material consumption. This higher cost impacts the overall budget, especially for large print jobs. Some home or office printers may also experience issues. These include jamming or poor feeding due to the paper’s thickness. Users should check printer specifications for compatibility.

Optimizing White Cardboard Selection for Printing Success

Printers must carefully select white cardboard to ensure successful printing outcomes. This involves matching material properties to press capabilities, considering the final product’s use, and verifying supplier quality.

Matching GSM and Stiffness to Press Requirements

Printers must match the white cardboard’s GSM and stiffness to their press requirements. Different printing presses handle various material thicknesses and rigidities. High-speed presses often require stiffer boards for smooth feeding and to prevent jams. Printers adjust machine settings for optimal performance. Selecting the correct GSM ensures efficient operation and minimizes production issues.

End-Use Application and Desired Print Quality

The intended end-use application directly dictates the required GSM for white cardboard. This balances a substantial feel with practical needs. For example, letterheads and basic documents typically use 90-120 GSM. Flyers and posters often require 150-200 GSM for more presence. Brochures and folded cards work well with 200-250 GSM, offering a good feel without difficult creasing. Business cards and premium stationery demand higher GSMs, usually 300 GSM and above, to communicate quality and durability. Packaging requires thicker, more rigid boards with even higher GSM equivalents, depending on the product.

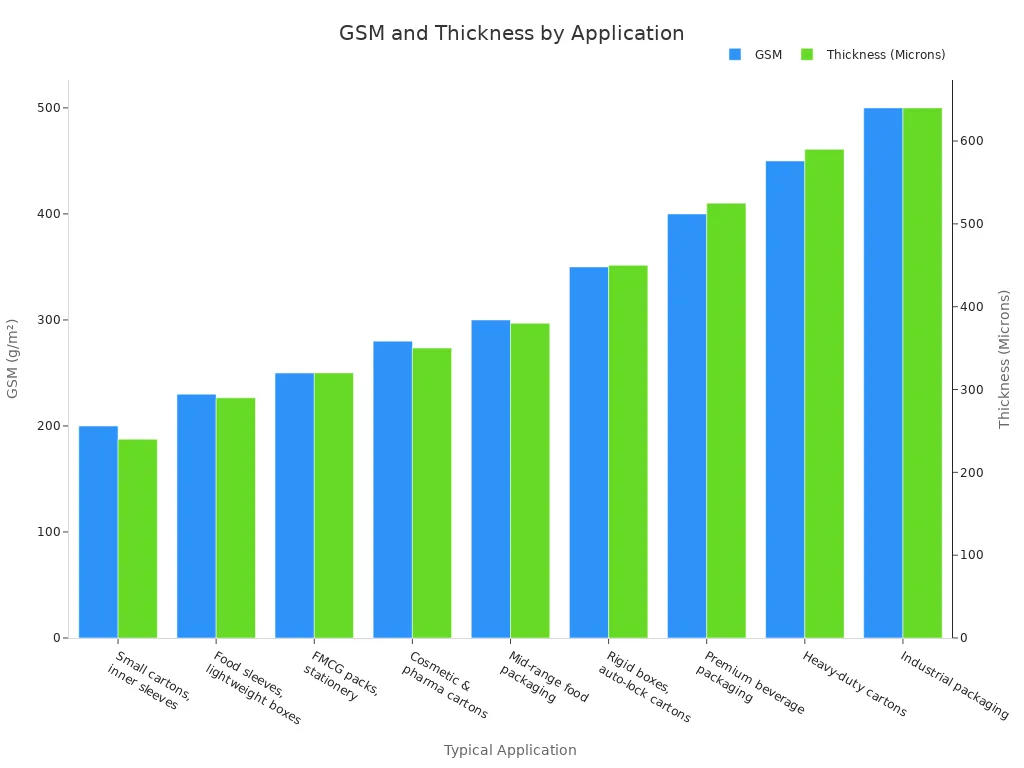

| GSM (g/m²) | Thickness (Microns) | Typical Application |

|---|---|---|

| 200 GSM | 230–250 µm | Small cartons, inner sleeves |

| 230 GSM | 280–300 µm | Food sleeves, lightweight boxes |

| 250 GSM | 310–330 µm | FMCG packs, stationery |

| 280 GSM | 340–360 µm | Cosmetic & pharma cartons |

| 300 GSM | 370–390 µm | Mid-range food packaging |

| 350 GSM | 440–460 µm | Rigid boxes, auto-lock cartons |

| 400 GSM | 500–550 µm | Premium beverage packaging |

| 450 GSM | 580–600 µm | Heavy-duty cartons |

| 500 GSM | 630–650 µm | Industrial packaging |

Higher GSM papers (300 GSM and up) offer greater durability for items like business cards. A higher GSM often conveys quality and luxury, as seen in wedding invitations. For items like brochures, GSM is crucial; papers that are too thick may crack when folded.

Supplier Specifications and Quality Control for White Cardboard

Suppliers provide critical specifications and quality control measures for white cardboard. They conduct GSM tests to measure paper weight, indicating thickness and quality. They also perform thickness or caliper tests using micrometers. These tests ensure the material meets specified standards like ISO 534.

Suppliers often provide ISO 9001 and 14001 certifications. They also offer FSC certification for sustainable sourcing. For food industry applications, food-contact safe certifications are available. Lab test reports for GSM, BF, and moisture content ensure quality.

Stiffness is a key indicator, often measured by Taber stiffness. Printing performance relies on a smooth, uniform surface, optimized for high-resolution printing. ISO 5628 and DIN 53 121 measure bending stiffness. ISO 8791-4 measures surface roughness, with lower values indicating smoother surfaces. ISO 3783 evaluates surface strength, assessing resistance to picking and blistering.

The GSM of white cardboard directly determines its stiffness. This critical property impacts every stage of the printing process. Businesses must select appropriate multi-GSM white cardboard based on specific stiffness requirements. This ensures optimal printing performance and achieves desired product outcomes.

FAQ

What does GSM mean for white cardboard?

GSM stands for Grams per Square Meter. It measures the weight of one square meter of cardboard. A higher GSM means heavier and generally thicker cardboard.

How does stiffness affect printing?

Stiffness helps cardboard feed smoothly through printers. It also ensures consistent ink adhesion and precise print registration. Stiffer boards prevent jams and improve print quality.

Why is medium GSM often preferred?

Medium GSM white cardboard offers a good balance. It provides enough stiffness for reliable printing without being too costly or difficult to handle. It suits many common printing jobs.

Post time: Jan-30-2026