Smart and sustainable food grade paper board packaging uses new technologies and eco-friendly materials to protect food and reduce waste. Many businesses now choose Ivory Board Paper Food Grade and Food Grade White Cardboard for safe, green solutions. Check out these trends shaping 2025:

| Trend | Impact |

|---|---|

| 25% with smart tech | Better food safety and shelf life |

| 60% recyclable/reusable | Eco-friendly and supports circular goals |

- The paper & paperboard market grows fast as companies and shoppers want safer, greener options.

- Normal Food-Grade Board and new materials help brands meet rising demand for natural packaging.

Key Drivers for Food Grade Paper Board Packaging in 2025

Consumer Demand for Eco-Friendly Packaging

Consumers today are more conscious of their environmental impact than ever before. This shift in mindset has fueled the demand for sustainable packaging solutions, especially in the food industry. The global eco-friendly food packaging market, valued at $190 billion in 2022, is projected to double to $380 billion by 2032, growing at a steady rate of 7.2% annually. Why? People want packaging that aligns with their values—recyclable, biodegradable, and non-toxic materials are now top priorities.

- Paper and paperboard packaging dominate this space, holding a 43.8% market share. Their clean, natural appearance and recyclability make them a favorite among eco-conscious shoppers.

- Recycled content packaging, made from post-consumer or post-industrial waste, is also gaining traction, with a projected market share of over 64.56%.

- Reusable packaging models, like refillable containers, are growing at a rate of 7.72%, driven by the need to reduce single-use waste.

Brands are responding to this demand with innovative solutions. For instance, DS Smith’s “GoChill Cooler,” made entirely from recyclable corrugated board, offers a sustainable alternative to traditional plastic coolers. These trends highlight how consumer preferences are reshaping the packaging landscape.

Regulatory Changes Impacting Food Grade Paper Board

Governments worldwide are stepping up to address the environmental crisis, and packaging regulations are at the forefront of these efforts. In California, the SB 54 Plastic Pollution Producer Responsibility Act mandates that all single-use plastics must be recyclable or compostable by 2032. This law is just one example of how regulations are pushing businesses to adopt sustainable practices.

The food and beverage industry, in particular, faces increasing pressure to comply with these rules. Many companies are turning to food grade paper board packaging as a solution. Its eco-friendly properties not only meet regulatory requirements but also appeal to environmentally conscious consumers.

E-commerce platforms are also playing a role. By reducing packaging waste and switching to sustainable materials, they’re setting new standards for the industry. These regulatory changes are not just challenges—they’re opportunities for businesses to innovate and lead the way in sustainability.

Environmental Pressures and Sustainability Goals

The environmental impact of traditional packaging materials, like plastics, is undeniable. Studies show that fossil-based barrier coatings in paper-based food packaging contribute significantly to pollution and health risks. To combat this, researchers are exploring biobased polymers such as cellulose and chitosan. These materials are biodegradable, non-toxic, and compatible with food safety standards.

However, the shift to sustainable packaging isn’t just about materials. It’s also about meeting global sustainability goals. Companies are adopting circular economy principles, focusing on reducing waste and reusing materials. Social pressures, like consumer demand for bio-based and recycled packaging, are driving these efforts.

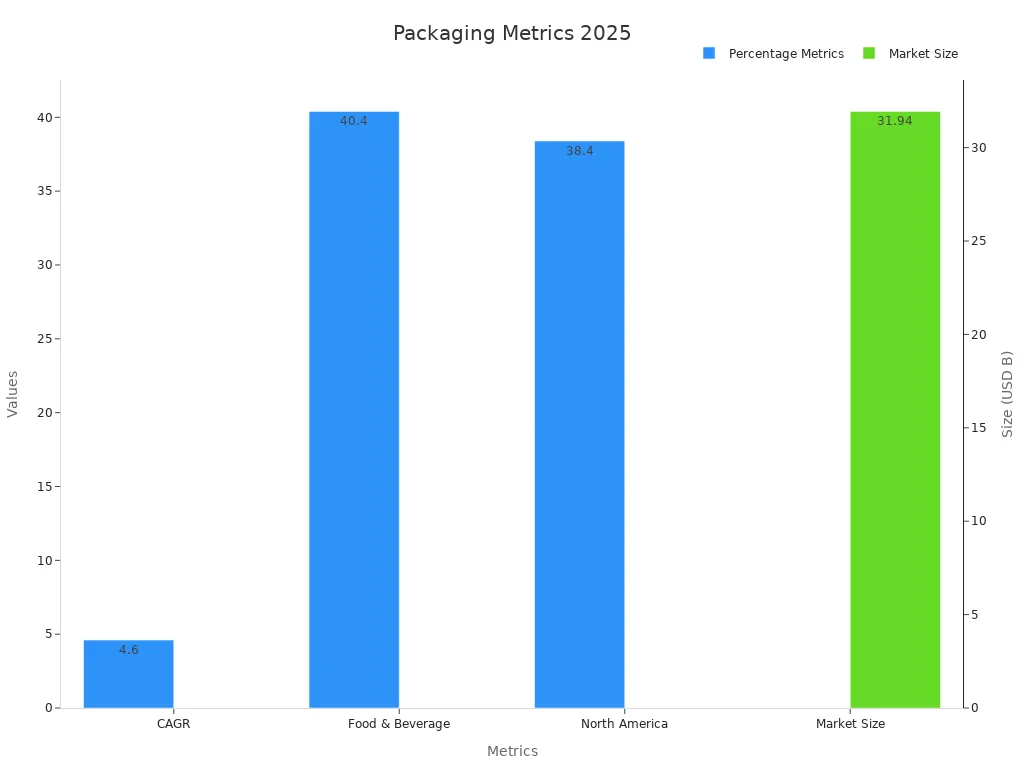

Here’s a snapshot of the market metrics shaping this shift:

| Metric | Value | Explanation |

|---|---|---|

| Market Size (2025) | USD 31.94 billion | Projected size of recyclable packaging market, indicating strong growth potential. |

| CAGR (2025-2032) | 4.6% | Compound annual growth rate showing steady expansion of the market. |

| Food & Beverage Market Share | 40.4% | Portion of recyclable packaging market driven by food and beverage sector demand. |

| North America Market Share | 38.4% | Largest regional share due to government regulations promoting recyclable materials. |

| Asia Pacific Growth | Fastest growing region | Driven by industrialization, sustainability initiatives, and evolving consumer preferences. |

These numbers underscore the urgency for businesses to embrace sustainable packaging solutions. By doing so, they can reduce their environmental footprint while staying ahead of market trends.

Smart Packaging Innovations in Food Grade Paper Board

Smart packaging is changing the way people think about food safety, freshness, and convenience. Companies now use new technologies to make packaging smarter and more helpful for both businesses and shoppers. These innovations help track food, keep it safe, and even tell you when it is time to eat or throw it away. Let’s look at some of the most exciting changes happening right now.

IoT and Sensor Technologies

IoT (Internet of Things) and sensor technologies are making food packaging much smarter. These tools help companies and consumers know more about the food inside each package. Here’s how they work and why they matter:

- IoT sensors track food storage and shipping conditions in real time. They watch things like temperature, humidity, and freshness.

- RFID tags and wireless sensors allow people to scan many packages at once without touching them. This helps during storage and transport.

- Some sensors can even check the pH level inside the package. This helps spot spoilage before it becomes a problem.

- Smart packaging can talk to computers and phones. It can send alerts if food gets too warm or starts to spoil.

- These systems help keep food safe, reduce waste, and make sure food stays fresh longer.

- AI and IoT together help farmers and companies predict crop yields, monitor food quality, and cut down on waste.

- New smart packaging is also becoming greener. Many companies now use low-cost, eco-friendly materials that work well with food grade paper board.

Smart packaging does more than just protect food. It helps everyone in the supply chain make better choices, from the farm to the table.

QR Codes and Digital Traceability

QR codes are popping up everywhere, especially on food packaging. They help people learn more about what they are buying and eating. Here’s why QR codes matter:

- Over 60% of half-gallon milk containers now have QR codes. This shows how common they have become in food packaging.

- Almost half of people who scan a QR code end up buying the product. QR codes help brands connect with shoppers and boost sales.

- More than half of shoppers say they like using QR codes to check product details and trace where their food comes from.

- QR codes became even more popular during the COVID-19 pandemic. People got used to scanning them for menus and payments, so now they feel comfortable using them on food packages.

- QR codes make it easy to track food from the farm to the store. They help reduce waste by allowing dynamic pricing and better inventory management.

QR codes turn every package into a source of information. Shoppers can scan and learn about freshness, origin, and even recipes.

AI-Driven Supply Chain Optimization

Artificial intelligence (AI) is helping companies manage food packaging and delivery in smarter ways. AI looks at lots of data and helps people make better decisions. Here’s what AI brings to the table:

| Region/Country | Market Size (Year) | Projected Growth |

|---|---|---|

| United States | $1.5 billion (2019) | Expected to reach $3.6 billion in coming decades |

| Global Market | $35.33 billion (2018) | Significant growth projected globally |

| Japan | $2.36 billion (N/A) | Second largest market |

| Australia, UK, Germany | N/A | Significant demand expected |

- AI helps companies predict when food will spoil and how much to order. This reduces waste and saves money.

- AI can spot problems in the supply chain before they get worse. It helps keep food safe and fresh.

- By using AI, companies can make sure food grade paper board packaging gets to the right place at the right time.

- AI also helps with recycling and composting. It supports a circular food supply chain, which is better for the planet.

Smart packaging innovations are not just about technology. They help people trust their food, keep it safe, and make the whole system more sustainable.

Sustainable Materials and Food Grade Paper Board Solutions

Recyclable and Compostable Paper Board

Many companies now choose recyclable and compostable paper board for their packaging. This choice helps lower environmental impact. Life-cycle assessments show that paper-based packaging creates less harm to the environment than many other materials. People see paper packaging as biodegradable and recyclable, which makes them more likely to buy products with these features. In fact, surveys show that over 80% of shoppers prefer packaging that is recyclable or made from recycled content. Companies have started using 100% recycled fiber paperboard that still looks great and works well. They also invest in new production facilities to make more recycled paperboard, which saves resources and supports a greener future.

Antimicrobial and Bio-Nanocomposite Materials

Food safety matters to everyone. New packaging uses antimicrobial and bio-nanocomposite materials to keep food fresh and safe.

- Antimicrobial films made from natural biopolymers can stop or kill harmful microbes.

- Adding antimicrobial agents to these films is a big step forward in food packaging.

- Nanotechnology makes these films stronger and better at keeping out air and moisture.

- Bio-nanocomposites work together to boost both safety and performance.

- Researchers focus on making these materials safe for the environment and good for food quality.

Reusable and Circular Packaging Designs

Reusable and circular packaging designs help cut down on waste. These designs play a big part in keeping food safe and fresh.

- Reusable packaging lowers the amount of trash and helps the planet.

- The Circular European Action Plan says all packaging in the EU must be reusable or recyclable by 2030.

- Brands that use reusable packaging often see more loyal customers.

- Companies must think about hygiene, safety, and how to get packaging back for reuse, but these challenges can be managed.

- Success depends on trust and knowledge from both brands and shoppers.

Food grade paper board fits well into these circular systems, making it a smart choice for the future.

Design and Branding Trends in Food Grade Paper Board Packaging

Minimalist and Functional Packaging Design

Minimalist packaging stands out on store shelves. Brands use clean designs, fewer graphics, and neutral colors to show authenticity and care for the environment. This style makes it easy for shoppers to spot important information. Functional features like resealable tops, easy-open tabs, and portion control help people use products with less hassle. Companies also add tamper-evident seals and clear labels to build trust. Studies show that minimalist packaging helps shoppers make decisions 46% faster and increases trust by 34%. People even say they will pay more for products with simple, eco-friendly packaging. Brands track success by watching sales, customer feedback, and how often people interact with smart packaging.

Customization and Personalization for Brands

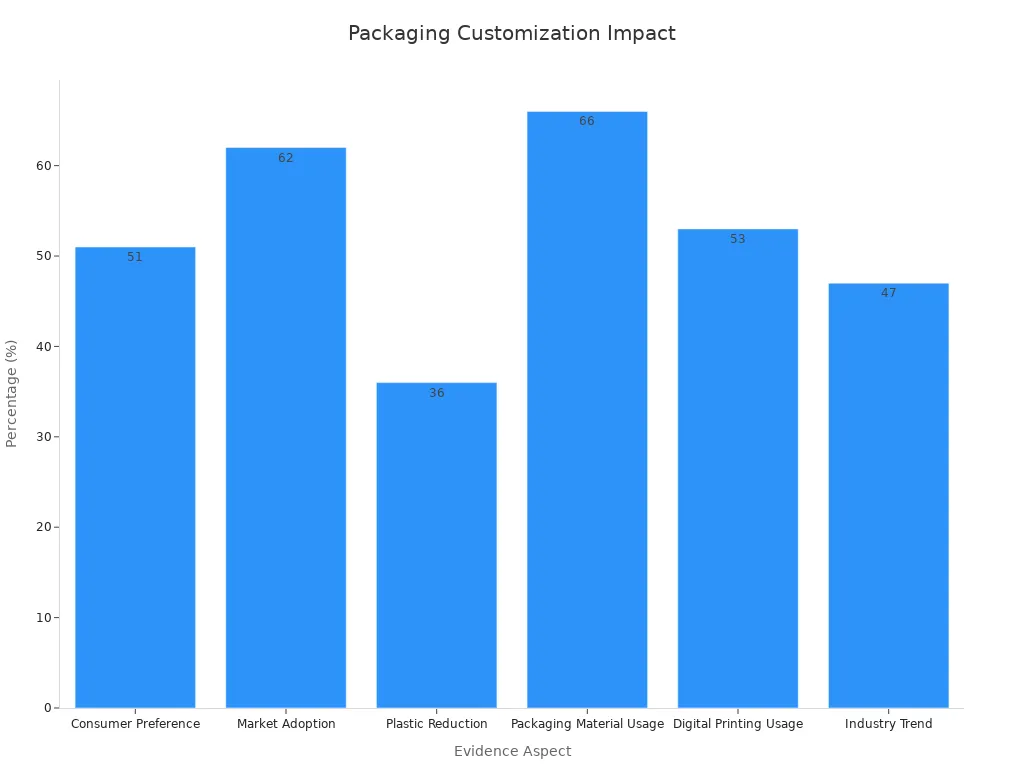

Brands love to tell their story through packaging. Custom printed folding cartons let them share values and product origins. Many companies use QR codes or even augmented reality to make packaging interactive. Special designs for holidays or limited editions catch the eye and boost excitement. Folding cartons can have embossing, foil stamping, or soft-touch finishes for a premium feel. Market research shows that over half of packaging innovations now focus on personalized, digitally printed designs. Nearly two-thirds of food and retail brands have switched to paperboard packaging, and more than half use digital printing to stand out.

| Aspect | Details |

|---|---|

| Personalized Designs | 51% of innovations focus on digital personalization |

| Paperboard Adoption | 62% of brands use paperboard packaging |

| Digital Printing | 53% of brands use digital printing for better visibility |

Eco-Friendly Branding and Consumer Engagement

Eco-friendly branding connects with shoppers who care about the planet. About 33% of people choose products from brands they see as green. More than half say they are more likely to buy items with reusable or recyclable packaging. Most shoppers—82%—are willing to pay extra for sustainable packaging. Brands that use recyclable materials and clear green messages build trust and keep customers coming back. The food and beverage industry leads the way, showing that eco-friendly branding is not just a trend but a smart business move.

Circular Economy and Food Grade Paper Board Packaging

Closed-Loop Systems and Material Recovery

Closed-loop systems help keep valuable materials in use and out of landfills. Many companies now use smart technology to sort and recover packaging. For example, AI-powered vision systems at recycling centers can spot and count different types of food packaging. These systems found that over 75% of recyclable polypropylene was clear or white, and most of it came from food and drink containers. That means a lot of packaging can go back into making new products instead of becoming waste.

AI tools, like Greyparrot’s Analyzer, make sorting faster and more accurate. They help workers see what materials come through and track how well the machines work. This leads to better recycling and less waste. In North America, more than 40 paper mills now accept paper cups, even those with plastic linings. This change happened because of teamwork between companies and groups like the NextGen Consortium. Now, more fiber from coated paper packaging gets recycled, which supports a circular economy.

Closed-loop systems powered by technology and teamwork give packaging a second life and help protect the planet.

Industry Partnerships for Sustainable Solutions

No company can build a circular economy alone. Industry partnerships play a big role in making packaging more sustainable. Groups like the NextGen Consortium and Closed Loop Partners bring together brands, recyclers, and innovators. They work on new ways to recover materials, improve recycling, and test new ideas.

These partnerships focus on real-world solutions. They run pilot programs, collect data, and share what works. By working together, they solve tough problems, like recycling paper cups with plastic linings. Their efforts show that when companies join forces, they can make big changes in how packaging is made, used, and recycled.

When industries team up, they create smarter systems and set new standards for sustainability.

Real-World Impact: Food Grade Paper Board Packaging Case Studies

Leading Brands Implementing Smart and Sustainable Packaging

Big brands have started to change how they package food. They want to protect the planet and keep food safe. Many companies now use smart packaging with sensors that track freshness. Some brands add QR codes so shoppers can learn where their food comes from. These changes help people trust what they buy. Brands also use recyclable and compostable materials to cut down on waste. They work with tech companies to make packaging smarter and greener. This teamwork helps brands meet new rules and keep customers happy. When brands lead the way, others often follow.

Startups Driving Innovation in Food Grade Paper Board

Startups bring fresh ideas to the packaging world. They use new materials and smart technology to solve big problems. For example, some startups use seaweed or mushrooms to make packaging that breaks down fast in nature. Others use sensors to check if food is still good to eat. Startups also use 3D printing and data tools to design better packages with less waste. Many work with bigger companies to share their ideas.

Here’s a look at some startups making a difference:

| Startup | What They Do | Key Products | Awards & Patents |

|---|---|---|---|

| Craste | Turns farm waste into packaging using special tech that saves water | Food-safe boxes, boards | Won grants, filed patents |

| SwapBox | Makes reusable bowls and cups for food and drinks | Microwavable bowls, coffee cups | Closed-loop recycling |

| Notpla | Uses seaweed to make edible, fast-biodegrading packages | Edible liquid pods | Won global awards, filed patents |

These startups show that new ideas can help the world use less plastic and keep food safe.

Smart and sustainable food grade paper board packaging is more than a trend—it’s a business must-have. Companies see strong growth ahead as the global food packaging market heads toward $613.7 billion by 2033.

| Benefit | Impact |

|---|---|

| Consumer Preference | 64% want sustainable packaging |

| Environmental Impact | 84.2% recycling rate in the EU |

| Competitive Advantage | 80% of brands adopting sustainability |

Businesses that act now gain loyal customers, help the planet, and stay ahead of the curve.

FAQ

What makes food grade paper board packaging sustainable?

Food grade paper board uses renewable materials. It often comes from recycled sources. Companies can recycle or compost it after use. This helps reduce waste.

How does smart packaging help keep food safe?

Smart packaging uses sensors or QR codes. These tools track freshness and storage conditions. Shoppers and companies get alerts if food quality changes.

Can food grade paper board packaging handle wet or oily foods?

Yes, many paper boards have special coatings. These coatings keep moisture and oil from soaking through. Food stays fresh and the packaging stays strong.

Post time: Jun-14-2025